In the world of manufacturing, efficiency isn't just a goal; it's the linchpin of profitability and competitiveness. However, achieving optimal efficiency is fraught with challenges, from the high costs of inefficiencies to common productivity hurdles that can stymie even the most well-organized production lines. One of the key areas where inefficiencies can be markedly reduced is in the grinding process, a critical phase in the manufacturing of numerous components across various industries.

Enter SUNNY MACHINE's Claw Grinding Wheel Technology, a revolutionary approach designed to address and overcome these productivity hurdles head-on. The technology is centered around an innovative grinding wheel design that offers precision, speed, and reduced waste, fundamentally changing the way manufacturers approach the grinding process.

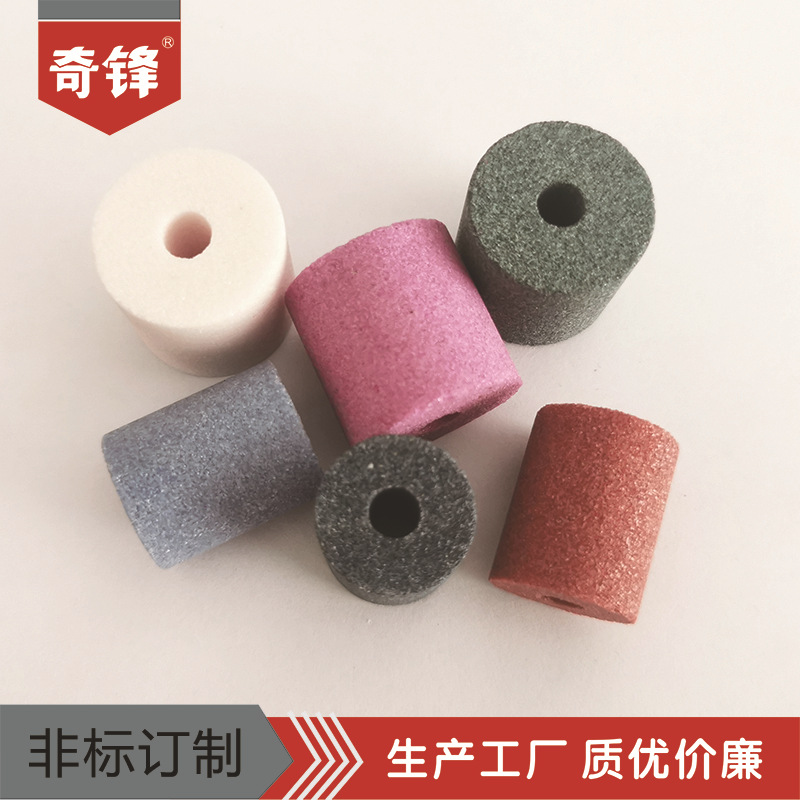

The Claw Grinding Wheel from SUNNY MACHINE is not just any grinding wheel. It comes with a unique design that enhances precision and accuracy while grinding, significantly reducing the material waste that is all too common with traditional grinding methods. Moreover, the design of these wheels has been optimized to increase production speed, making it a win-win for manufacturers looking to boost their efficiency.

Real-world applications of SUNNY MACHINE's technology underscore its effectiveness. For instance, an automotive parts manufacturer reported a marked improvement in the production time of engine components, attributing the efficiency gains to the precision and speed of SUNNY MACHINE's Claw Grinding Wheel. Similarly, an aerospace components producer noted not just the reduction in production time but also the substantial decrease in material waste, leading to cost savings and a more environmentally friendly production process.

When compared with traditional grinding methods, SUNNY MACHINE's Claw Grinding Wheel stands out. Traditional methods are often time-consuming, cost-inefficient, and less environmentally friendly due to higher waste production. SUNNY MACHINE's technology, on the other hand, addresses each of these issues head-on, offering a solution that is both faster and more cost-effective, while also reducing the environmental impact of the grinding process.

Implementing SUNNY MACHINE's technology is a straightforward process designed to integrate seamlessly with existing manufacturing systems. The company provides a step-by-step guide for installation, along with comprehensive training and support, ensuring a smooth transition to the new technology and immediate realization of its benefits.

Looking ahead, the future of manufacturing is poised for even greater advancements. The role of automation and artificial intelligence (AI) is expected to grow, further enhancing efficiency and productivity. Moreover, sustainable manufacturing practices are becoming increasingly important, with technologies like SUNNY MACHINE's Claw Grinding Wheel playing a key role in reducing waste and promoting environmental sustainability.

For those considering SUNNY MACHINE's technology, common questions often revolve around maintenance and durability, compatibility with various manufacturing needs, and the expected return on investment (ROI). The company assures that its Claw Grinding Wheels are designed for durability and are compatible with a wide range of manufacturing applications. Moreover, the significant efficiency gains typically result in a rapid ROI, making it a wise investment for manufacturers looking to improve their bottom line.

Getting started with SUNNY MACHINE is easy. Interested manufacturers can contact the company's sales and customer support team for detailed information on planning, installation, and setup. Additionally, SUNNY MACHINE offers success tips from existing users, ensuring new customers can quickly achieve and even exceed their efficiency goals.

Testimonials from satisfied customers further attest to the benefits of SUNNY MACHINE's Claw Grinding Wheel Technology. Quotes from various industry leaders highlight not just the efficiency improvements but also the positive impact on product quality and overall production costs. Before and after efficiency metrics provide tangible evidence of the technology's impact.

For those looking to make the most of SUNNY MACHINE's technology, the company provides guidance on troubleshooting common issues and tips for maximizing the lifespan and effectiveness of the claw grinding wheel. This ensures that manufacturers can enjoy the benefits of the technology for years to come.

In conclusion, SUNNY MACHINE's Claw Grinding Wheel Technology represents a significant leap forward in manufacturing efficiency. By addressing common challenges with innovative solutions, SUNNY MACHINE is helping to revolutionize the manufacturing landscape, paving the way for a future where efficiency, quality, and sustainability go hand in hand.