Exploring the Power of Small Grinding Wheels

When it comes to precision and fine-detail work, smaller tools often yield significant prowess. This is especially true for small grinding wheels which provide exceptional performance in compact packages. In this article, we delve into the world of small grinding wheels, exploring their importance, application areas, benefits, selection criteria, and emerging trends.

Understanding Small Grinding Wheels

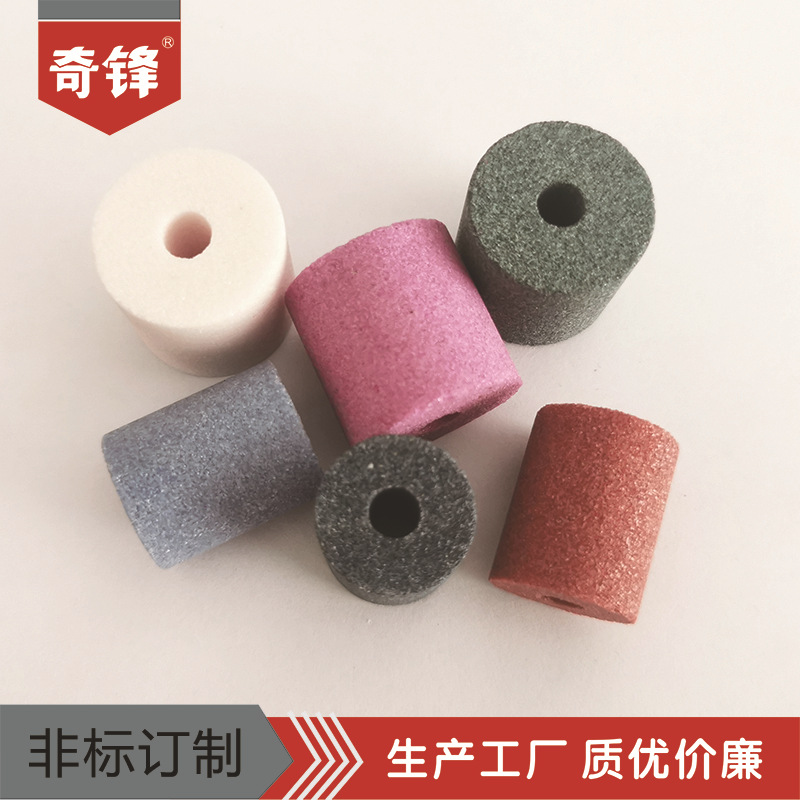

Small grinding wheels are specialized abrasives that excel at precise materials removal on a minute scale. Typically measuring up to a few inches in diameter, these wheels stand out from larger counterparts by offering increased control and accuracy suitable for intricate tasks. Composed of materials such as aluminum oxide, silicon carbide, or diamond, they come in varying types including flat, cup, and dish-shaped designs tailored for specific uses.

The paramount difference between small and large grinding wheels lies not just in size but also in application intent. While large wheels cater to heavy-duty material shaping, small wheels thrive on precision, making them indispensable for detail-oriented professions.

Precision and Detail Work

Small grinding wheels are pivotal in executing tasks requiring meticulous attention to fine details. Their ability to produce high-quality finishes makes them essential in various artisanal and technical fields.

- Jewelry Making: Crafting intricate jewelry pieces demands unparalleled finesse. Small grinding wheels allow jewelers to shape precious metals and gemstones with pinpoint accuracy, ensuring every piece meets aesthetic and functional standards.

- Model Building: For hobbyists and professionals alike, model building involves detailing miniature components. Utilizing small grinding wheels facilitates creating lifelike models where every tiny part fits perfectly.

- Dental Applications: Dentistry requires precision instruments for repairing teeth and fitting crowns. Small grinding wheels help dental professionals achieve clean cuts and smooth surfaces, crucial for patient comfort and prosthetic effectiveness.

Versatility in Various Industries

The scope of small grinding wheels extends beyond artistic and medical fields, marking their significance across diverse industries.

- Automotive Industry: From engine components to body parts, small grinding wheels contribute to manufacturing and maintaining automotive excellence. They enable detailed work on tight spaces, enhancing vehicle performance and longevity.

- Aerospace Industry: The aerospace sector demands impeccable precision for safety-critical components. Small grinding wheels assist in fabricating and maintaining aircraft parts, ensuring adherence to strict industry standards.

- Electronics and Semiconductor Manufacturing: In electronics, even minor discrepancies can lead to malfunction. These grinding wheels ensure flawless production of microchips and circuit boards integral to modern technology.

Benefits of Using Small Grinding Wheels

Employing small grinding wheels offers several advantages conducive to efficient and effective operations.

- Enhanced Control and Accuracy: Smaller size allows for better maneuverability, enabling users to craft with greater precision.

- Reduced Material Waste: Their precision minimizes material wastage, translating to cost savings and resource efficiency.

- Cost-effectiveness for Small-scale Projects: Especially beneficial for projects that do not require large-scale equipment investments, providing excellent value for money.

Selection Criteria for Small Grinding Wheels

Selecting the right small grinding wheel entails considering multiple factors to fulfill specific requirements effectively.

- Identifying the Right Grit Size: Finer grit sizes are ideal for polish and finish, while coarser grits cater to material removal tasks.

- Choosing the Appropriate Bond Type: Depending on the material being worked on, select resin, vitrified, or metal bonds to achieve optimal performance.

- Considering Wheel Shape and Size: Different shapes (flat, cup, dish) fit distinct applications; choosing the correct one ensures suitability and effectiveness.

Tips for Optimal Use

Maximizing the potential of small grinding wheels requires adhering to best practices regarding usage and maintenance.

- Proper Handling and Storage: Handle with care to avoid damages, store in a dry place to prevent moisture impact.

- Recommended Safety Practices: Always wear protective gear—gloves, goggles—and ensure adequate ventilation during use.

- Maintenance and Longevity: Regularly inspect for wear and tear, dress the grinding surface periodically to maintain sharpness and efficacy.

Case Studies and Success Stories

Several real-world examples illustrate the success achieved using small grinding wheels.

Real-world Examples Showcasing Efficiency: In a recent project involving semiconductor manufacturing, incorporating small grinding wheels significantly improved product quality, reducing defects by 30%.

Testimonials from Industry Professionals: "The versatility and precision of small grinding wheels have revolutionized our processes," says an automotive engineer from a leading firm.

Comparative Analysis with Alternative Tools: Compared to rotary burrs, small grinding wheels offer superior surface finishing capabilities and extended tool life.

Future Trends and Innovations

The domain of small grinding wheels continues to evolve with advancements steering toward enhanced performance and broader adoption.

- Emerging Technologies in Grinding Wheels: Incorporation of nano-materials and enhanced bonding techniques promise higher durability and efficiency.

- Advancements in Materials and Manufacturing Processes: New alloys and synthetic diamonds are setting new benchmarks in grinding technology.

- Predictions for Market Growth and Industry Adoption: As industries increasingly prioritize precision and sustainability, the market for small grinding wheels is poised for significant expansion.

In conclusion, small grinding wheels embody the perfect blend of precision, versatility, and efficiency. Whether you are engaged in delicate artistry or stringent industrial processes, these compact tools deliver remarkable results. Discover the range of premium small grinding wheels available through SUNNY MACHINE and elevate your craftsmanship today.