Understanding Small Grinding Wheels

Small grinding wheels are indispensable tools in precision work, ranging from detailed metalwork to fine jewelry making. Characterized by their compact size and high accuracy, these tools often come with specific size specifications and diverse material compositions, such as aluminum oxide, silicon carbide, and even diamond.

Common Types and Variations

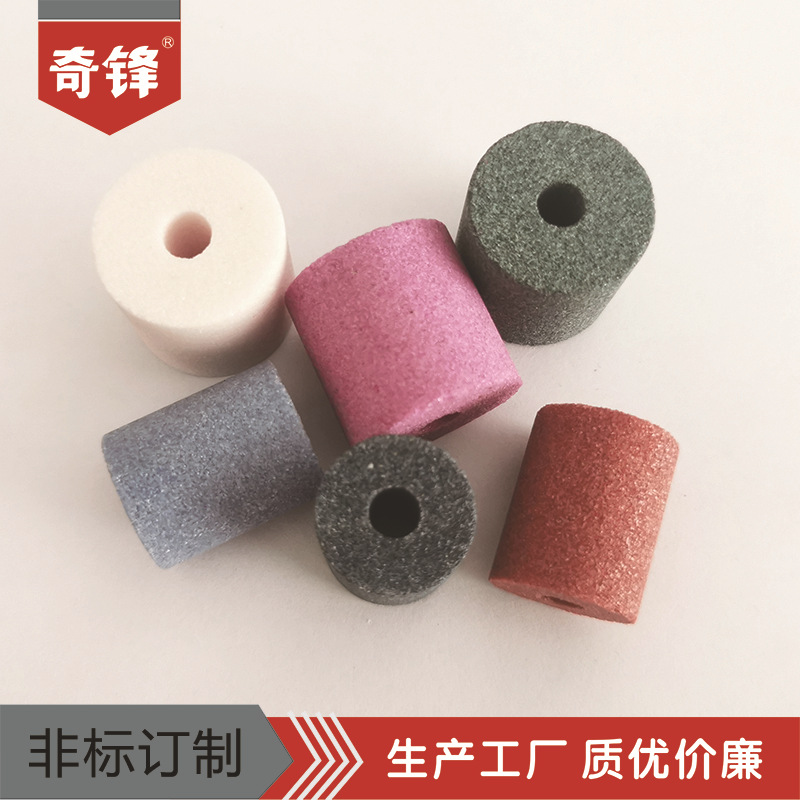

The range of small grinding wheels includes several types tailored for different tasks. Cylindrical grinding wheels allow for the efficient grinding of circular parts. Conical grinding wheels feature a tapered design perfect for precise surface contouring. Diamond-tipped grinding wheels offer superior durability and performance, ideal for hard materials like glass or ceramics.

Advantages of Using Small Grinding Wheels

Enhanced Precision

One significant advantage is the enhanced precision they offer. Ideal for fine-tuning details and intricate shaping, small grinding wheels ensure minimal material waste during operations, contributing to both cost efficiency and environmental sustainability.

Versatility in Applications

These wheels can handle a variety of materials—including metal, glass, and ceramics—making them highly versatile. Moreover, they're adaptable to numerous grinding tasks, whether it be cutting, sharpening, or polishing, thereby expanding their utility across multiple industries.

Technical Aspects and Performance

Power and Efficiency

Small grinding wheels must be compatible with various motor powers while also offering speed control mechanisms to manage RPM (Revolutions Per Minute). This ensures efficient and targeted grinding without compromising on quality.

Durability and Longevity

High wear resistance is crucial for prolonged use. Regular maintenance and care tips involve frequently inspecting the wheel for damage and ensuring proper storage to maintain their effectiveness over time.

Practical Applications in Various Industries

Jewelry Making

In jewelry making, small grinding wheels excel in crafting intricate designs and executing fine detailing. Commonly used tools include cylindrical and single concave grinding wheels, which help achieve polished finishes required for high-quality pieces.

Aerospace Engineering

Aerospace engineering demands extreme precision in component manufacturing, where material integrity cannot be compromised. The adaptability and minute accuracy provided by small grinding wheels make them essential in this field.

Medical Equipment Manufacturing

In medical equipment manufacturing, especially in crafting surgical instruments, small grinding wheels are crucial. They ensure the required precision and sterility levels necessary for safe usage in medical settings.

Tips for Selecting the Right Small Grinding Wheel

Assessing the Project Requirements

Selecting the right grinding wheel starts with assessing your project's requirements, including material hardness and type. Desired finish and accuracy also play pivotal roles in determining the appropriate wheel type.

Evaluating Wheel Quality

Investigate brand reliability and customer reviews when choosing a grinding wheel. Trusted brands often provide better quality products that meet industry standards, reducing the likelihood of operational issues.

Safety Considerations

Proper Handling and Usage

Using personal protective equipment (PPE) is non-negotiable for safety. Proper mounting and alignment of the grinding wheel further prevent accidents, ensuring a safe work environment.

Preventive Measures

Always inspect the wheel before use for any cracks or defects and practice safe storage methods to prolong its life span and usability.

Expert Insights and Recommendations

Interviews with Professional Craftsmen

Professionals highlight real-world examples illustrating the benefits and applications of small grinding wheels, emphasizing best practices and successful project outcomes.

Case Studies

Detailed case studies show how small grinding wheels play a critical role in achieving impeccable results in various projects, providing useful lessons and best practices for users.

Resources and Further Reading

Recommended Tools and Brands

For reliable performance, brands like SUNNY MACHINE are recommended. Their range includes high-quality small grinding wheels and accessory kits designed for diverse applications.

Educational Materials

Tutorials, guides, workshops, and training sessions are valuable resources for mastering the use of small grinding wheels. These materials assist both novice and experienced craftsmen in enhancing their skills.